New homeowners often focus on visible systems first. Roofs, plumbing, and appliances get attention. Backup generators stay overlooked. This gap creates preventable problems. Generator maintenance and repairs require planning from day one. Waiting invites stress during outages.

Generators sit idle for long stretches. That idle time causes quite a lot of damage. Oil degrades, and seals dry. Batteries weaken without warning. Over time, small issues pile up. Homeowners rarely notice until power disappears. Early awareness changes that outcome.

Many buyers inherit generators from previous owners. Maintenance history is often unclear. Assumptions replace facts. In reality, unknown wear hides inside the system. Baseline inspections reveal real conditions. That step sets expectations and prevents surprise failures later.

Treating a Generator Like a “Set and Forget” Appliance

Generators differ from standard appliances. Refrigerators run daily and show warning signs. Generators stay silent until emergencies. Because of this, problems remain hidden. Owners assume silence equals health. That assumption fails often.

Mechanical parts need movement. Engines suffer from inactivity. Fuel systems clog without flow. Moisture builds in exhaust lines. Gradually, performance drops. Scheduled exercise cycles keep parts functional and ready.

Ignoring routine checks shortens generator lifespan. Filters clog, and belts crack. Electrical connections loosen over time. Eventually, failures occur under load. Simple monthly checks catch these issues early.

Skipping Load Testing After Installation

Initial installation tests feel reassuring. The lights turn on briefly. That test feels complete. Yet, real outages stress systems differently. Full household demand exposes weak points fast.

Load testing simulates actual conditions. It measures voltage stability and engine response. Without it, engines run inefficiently. Carbon builds inside cylinders. Over months, that buildup reduces power output.

Homeowners often add appliances later. Air conditioners and pumps increase demand. As usage grows, original settings may fail. Periodic load testing confirms capacity still matches household needs.

Failing to Create a Maintenance Record and Service Plan

Many homeowners rely on memory for generator care. That approach fails quickly. Written records show what was serviced and when. They reveal patterns before problems grow. At the outset, documentation builds long-term reliability.

Service logs help technicians diagnose issues faster. Missed intervals become obvious. Warranty claims move more smoothly with proof. In practice, organized records reduce guesswork and downtime.

Creating a maintenance plan marks the first step towards a new chapter of responsible ownership of your new home. This is especially important if you are moving out for the first time to your new home. It shifts care from reactive to planned. That change improves performance and extends system life.

For many homeowners, records feel unnecessary at first. Over the long run, they become essential tools. Clear documentation becomes the most important step towards a new chapter of stress-free backup power management.

Ignoring Fuel Quality and Storage Issues

Fuel problems cause frequent generator failures. Gasoline degrades quickly. Diesel attracts water and bacteria. Propane regulators collect debris. Each fuel type carries specific risks.

Stale fuel gums injectors and carburetors. Filters clog faster than expected. Engines struggle during startup. Consequently, generators stall under pressure. Proper fuel storage prevents these issues.

Fuel rotation schedules matter. Stabilizers slow down the breakdown but do not stop it. Tanks need inspection for moisture. In addition, lines require flushing during service. Clean fuel supports reliable operation during long outages.

Generator Maintenance and Repairs That Start Too Late

Many homeowners delay service to save money. That decision often backfires. Generator maintenance and repairs work best before failure. Preventive care costs less than emergency repairs.

Small leaks become major damage. Sensors drift out of range. Cooling systems lose efficiency. Over time, engines overheat or shut down. Early service avoids cascading failures.

Emergency repairs often require rushed parts. Technicians work under pressure. Downtime increases during outages. By contrast, scheduled service allows planned corrections and testing. That approach protects both the system and the budget.

Overlooking Battery Health and Charging Systems

The battery controls startup reliability, and that’s why they are important for your home. Most failures trace back to weak batteries. Still, many homeowners ignore them. Chargers fail quietly and go unnoticed.

Batteries lose capacity with age. Heat accelerates that loss. Cold weather exposes weakness quickly. During outages, engines fail to crank. Routine testing reveals declining performance early.

Charging systems also need inspection. Loose connections reduce charge flow. Corrosion blocks terminals. Meanwhile, control boards may misread voltage. Annual battery service prevents silent failures.

Attempting DIY Repairs Without Proper Knowledge

DIY repairs feel tempting during outages. Online videos make fixes appear simple. However, generators combine fuel, electricity, and software. Mistakes cause serious damage.

Improper adjustments affect engine timing. Incorrect wiring damages control boards. Safety risks rise fast. In many cases, repairs cost more afterward. Warranty coverage often disappears.

Professional technicians use diagnostic tools. They follow the manufacturer’s standards. As a result, repairs last longer and perform correctly. Skilled service protects reliability and safety.

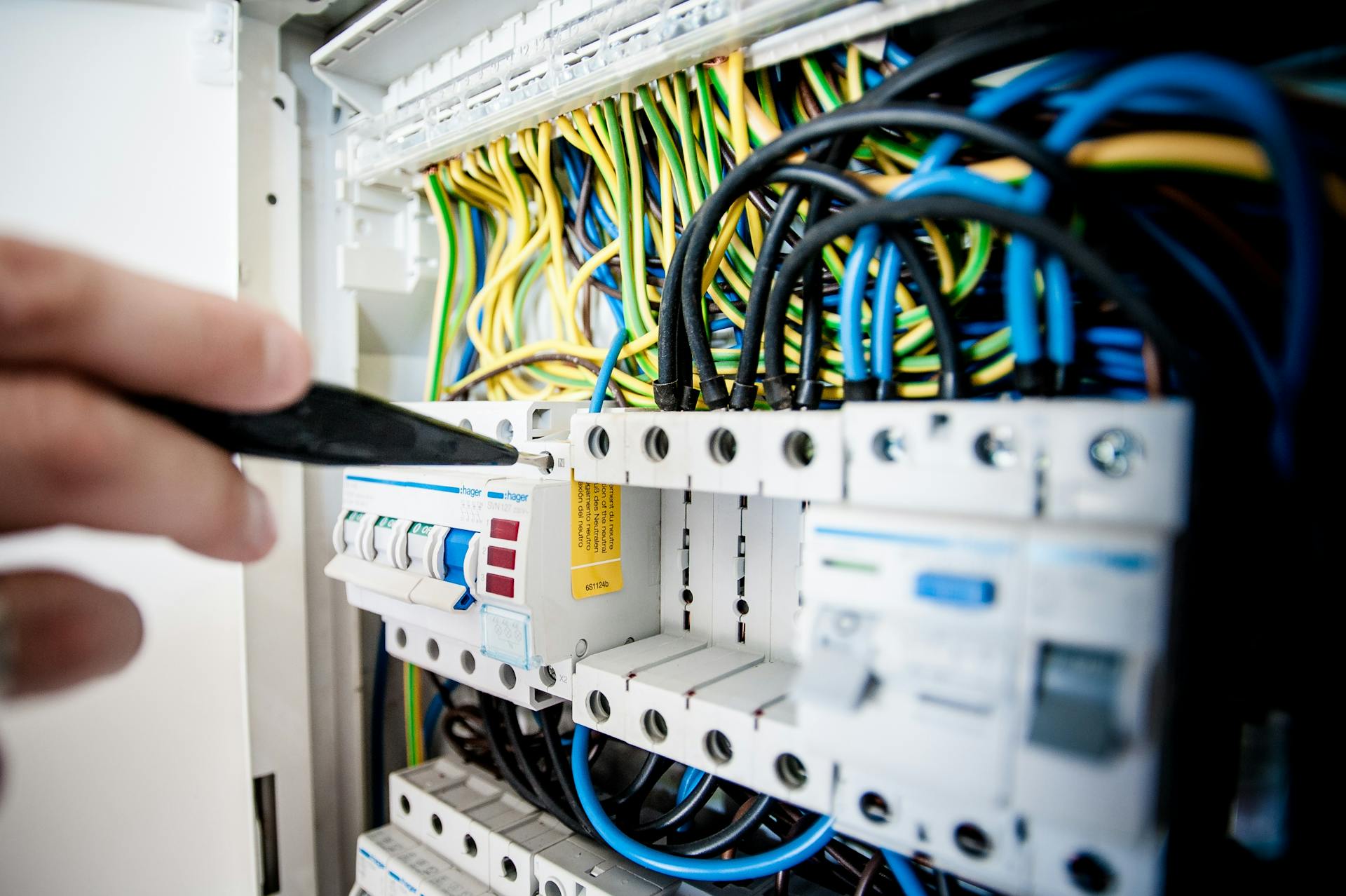

Failing to Maintain Transfer Switches and Controls

Transfer switches manage power flow safely. Without them, generators cannot serve homes. Despite this, they receive little attention. Dust and pests disrupt contacts.

Switches must operate instantly during outages. Delays cause voltage drops. Appliances suffer damage. At times, generators run, but power never transfers.

Control panels also require calibration. Sensors drift over the years. Software updates may be needed. Therefore, inspections should include controls, not just engines. Proper testing ensures seamless power delivery.

Forgetting Environmental and Placement Factors

Outdoor generators face constant exposure. Rain, heat, and debris attack components. For instance, blocked airflow raises engine temperature. That heat shortens component life.

Poor placement worsens these issues. Tight spaces trap exhaust and moisture. Drainage problems cause rust. Meanwhile, vegetation restricts airflow. Clear surroundings protect system health.

Wildlife also causes damage. Rodents chew wiring. Insects build nests in panels. Seasonally, snow and ice block vents. Routine cleaning reduces environmental risks.

Summary: Smart Habits Prevent Costly Generator Failures

Generator problems rarely appear suddenly. They grow from ignored details. Generator maintenance and repairs demand steady attention. Early habits prevent stress during outages.

Consistent inspections reveal wear early. Fuel care supports reliable starts. Battery testing ensures readiness. In the end, proactive care saves money and protects comfort. A maintained generator delivers peace of mind when power fails.